Cylinder hydrotesting, also known as the hydrostatic stretch test, is a process used to test the strength and integrity of gas cylinders. It involves filling the cylinders with water and pressurizing them to check for leaks and ensure they can withstand the pressure they are designed to hold. This testing is essential for ensuring the safety and reliability of gas cylinders used for various purposes.

Why do we need Cylinder hydrotesting?

Well, it’s all about safety! Imagine you have a gas cylinder that you use for your workforce in uncertain conditions. Over time, the cylinder can undergo stress and wear due to the repeated filling and use. This can weaken the cylinder, making it unsafe to use. To avoid any potential accidents or gas leaks, periodic hydrotesting is necessary.

According to safety guidelines, all high-pressure seamless gas cylinders must undergo hydro testing every five years. For some specific gas cylinders, the testing might be required every two years or as specified by the safety authorities.

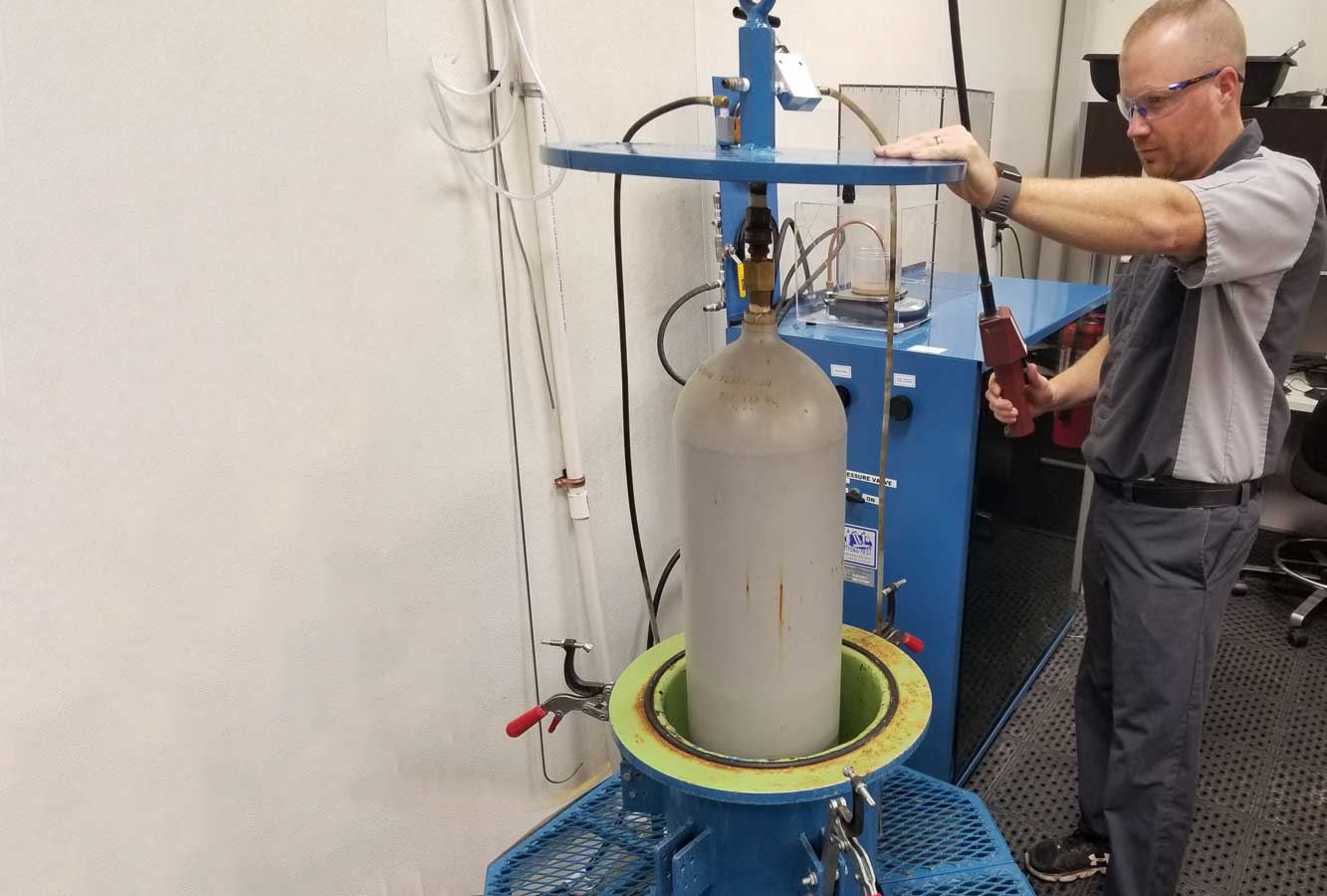

During hydrotesting, the cylinder is filled with water and pressurized to a level higher than its usual working pressure. This helps to check the elasticity of the cylinder’s material. Elasticity is the ability of the cylinder to expand slightly when filled with gas and contract back to its original shape when emptied. With repeated use, this elasticity may reduce, making the cylinder unsafe.

The hydrotesting process ensures that the cylinder’s material remains elastic enough to handle gas pressure safely. After the test, the cylinder is carefully checked for any leaks or deformities. If everything is within the specified safety limits, the cylinder is considered fit for use for the next period.

Regular hydrotesting is essential to identify any potential weaknesses in the cylinder’s structure and prevent accidents or gas leaks. It’s like giving the cylinder a health check-up to make sure it’s in perfect condition. By following these safety measures, we can use gas cylinders with confidence, knowing that they are safe and reliable for our daily needs.

In conclusion, cylinder hydrotesting is a critical safety process that checks the strength and integrity of gas cylinders. By periodically testing them, we ensure that they remain safe and reliable for use in our homes, industries, and various other places. This way, we can enjoy the benefits of gas cylinders without worrying about any potential risks or hazards. Safety always comes first!

Why Choose ServeGas?

We at ServeGas, provide this key service of hydrotesting of cylinders in Doha and Industrial areas of Qatar.

ServeGas stands out as your ideal choice for hydro testing gas cylinders in Doha, Qatar. With the capability to Hydro Test cylinders up to 700 Bar Test Pressure, ServeGas brings a wealth of experience, expertise, and advanced instruments to ensure a meticulous testing procedure in line with approved global regulations. Our esteemed Hydraulic Test Lab is fully recognized and equipped to handle various types of cylinders, including Steel, Aluminum, Carbon Composite, and welded cylinders